Characteristic

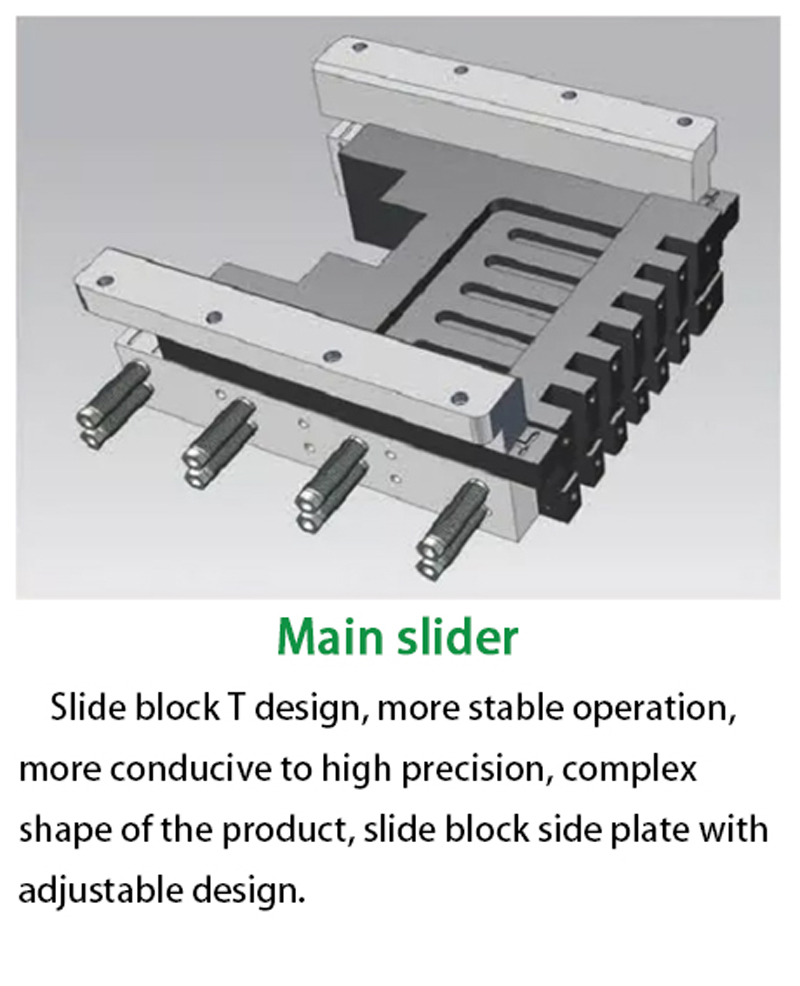

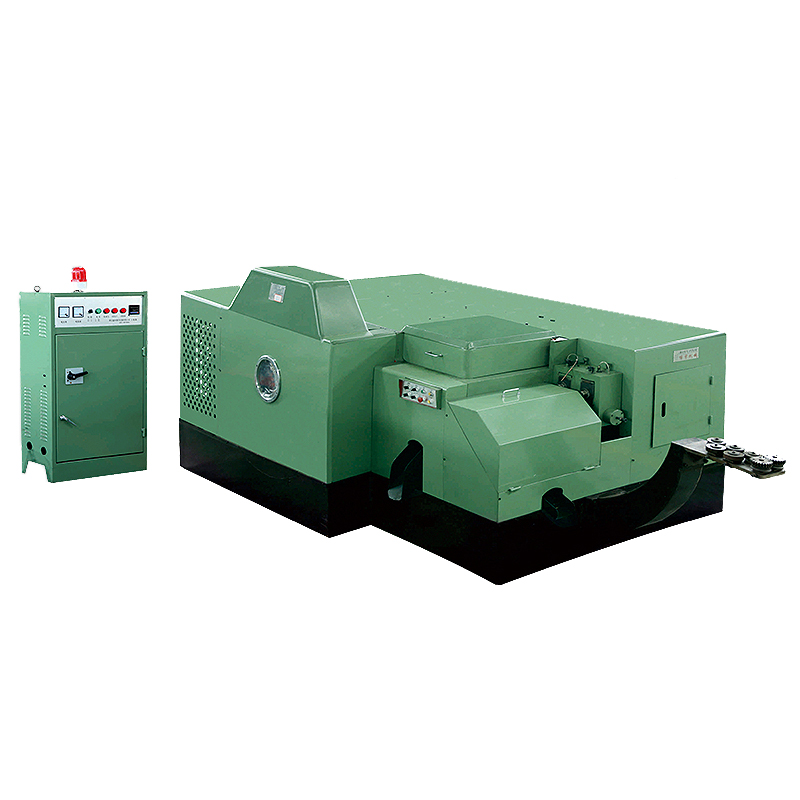

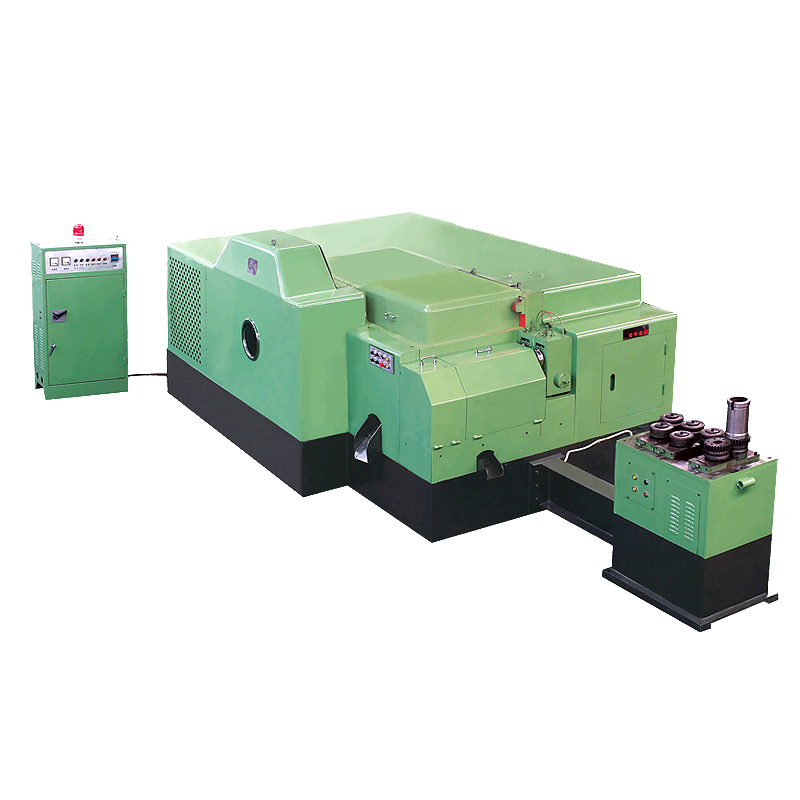

●The best conditions of various mold specifications in order to achieve a molding products. ●The high rigidity of the basic structure provides stable and reliable cold forging. ●Advanced automated configuration will help the industry to improve production efficiency. Reduce costs, and increase profits. ●The design and implementation of the punch and workpiece slide mold meet processing all kinds of special items. ●It has a compact structure and has a "anti-damage" insurance agency. ●The mechanism of nut machine is easy to assemble, with strong jacking force and easy adjustment.Optional Configuration

1. Single speed,double speed of servo motor. 2. The feeding device improves the feeding precision. 3. Inverter, stepless speed regulation in a certain range 4. The power unit is equipped with a pneumatic clutch to reduce shock and start current, and to protect the electrical and motor. 5. PKO 6. Bearing standard type. 7. Lengthening of copper sleeve.BOYU cold heading machine for nut making 11B-17B

| Item | 11B | 12B20L | 14B25L | 14B30L | 17B25L | 17B30L | 17B35L | 11B20LT | 11B40LT | 11B50LT | 12B20LT | 14B25LT | 14B30LT | 14B40LT | 14B60LT | 14B80LT | 17B25LT | 17B30LT | 17B40LT | 17B70LT | |

| Forging station(mm) | 6s | 6s | 6s | 6s | 6s | 6s | 6s | 6s | 6s/7s | 6s/7s | 6s | 6s | 6s | 6s/7s | 6s/7s | 6s/7s | 6s | 6s | 6s/7s | 6s/7s | |

| Max. cut-off diameter(mm) | 11 | 12 | 14 | 14 | 17 | 17 | 17 | 11 | 11 | 11 | 12 | 14 | 14 | 14 | 14 | 14 | 17 | 17 | 17 | 17 | |

| Cut-off length(mm) | 3.3 ~ 22 | 3.3 ~ 22 | 5 ~ 25 | 7 ~ 32 | 6 ~ 25 | 6 ~ 31 | 7.5 ~ 37 | 3.3 ~ 22 | 6 ~ 40 | 8.5 ~ 54 | 3.3 ~ 22 | 5 ~ 25 | 7 ~ 33 | 10.2 ~ 42 | 11.6 ~ 63 | 23 ~ 85 | 6 ~ 25 | 6 ~ 31 | 8 ~ 41.5 | 17.5 ~ 73 | |

| Kick-Out Length(mm) | 27 | 28 | 33 | 39 | 33 | 40 | 45 | 27 | 44 | 58 | 27 | 33 | 39 | 46 | 70 | 90 | 33 | 40 | 46 | 80 | |

| Center Distance(mm) | 50 | 50 | 60 | 60 | 70 | 70 | 70 | 50 | 50 | 50 | 50 | 60 | 60 | 60 | 60 | 60 | 70 | 70 | 70 | 70 | |

| Forging Power(Ton) | 65 | 75 | 90 | 90 | 120 | 120 | 120 | 65 | 65 | 65 | 65 | 90 | 120 | 120 | 120 | 120 | 140 | 140 | 200 | 200 | |

| Main motor(HP) | 15 | 15 | 30 | 30 | 30 | 30 | 30 | 15 | 15 | 15 | 15 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 40 | 40 | |

| Oil consumption (about 200L per barrel) No.8 or No.10 cold heading oil | 800L | 800L | 1000L | 1000L | 1200L | 1200L | 1200L | 800L | 800L | 800L | 800L | 1000L | 1000L | 1000L | 1000L | 1000L | 1200L | 1200L | 1200L | 1200L | |

| Machinery weight(Ton) | 4.5T | 6T | 8.5T | 9T | 11.5T | 11.5T | 11.5T | 4.5T | 6T/6.5T | 6T/6.5T | 6T | 8.5T | 9T | 9.5T/10T | 10T/10.5T | 10.5T/11T | 11.5T | 11.5T | 12T/12.5T | 12.5T/13T | |

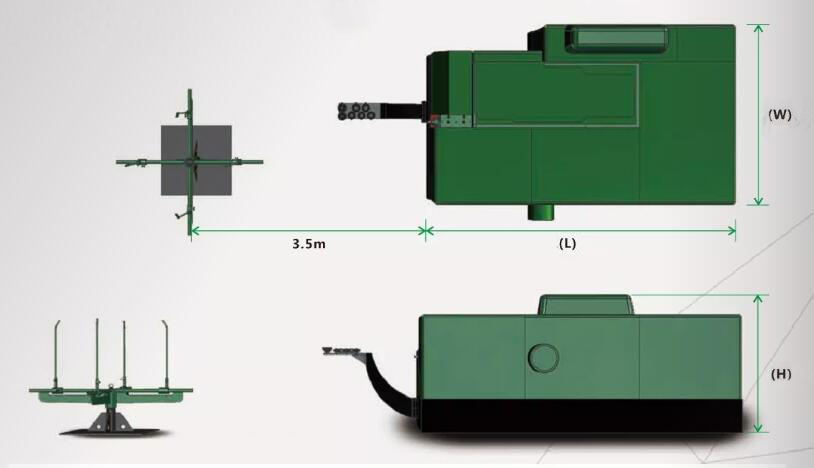

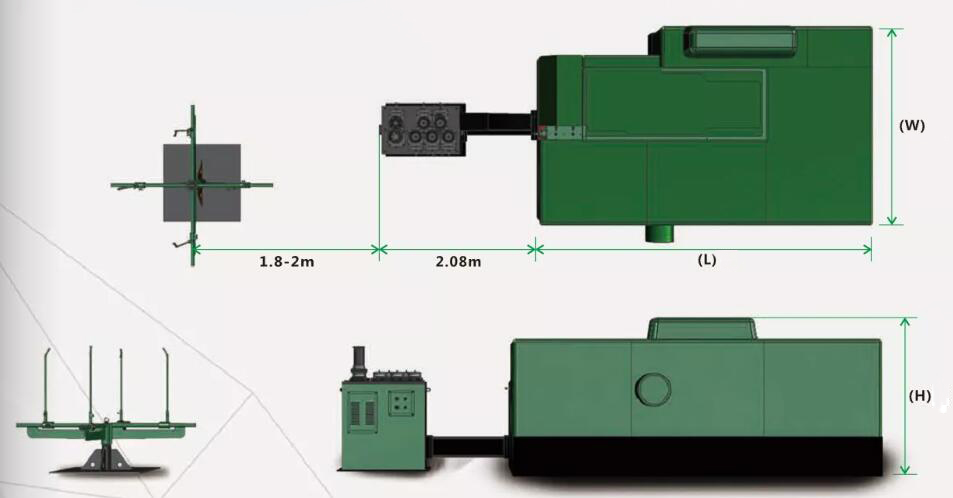

| Size(m) | L | 2.5 | 2.8 | 3 | 3.3 | 3.6 | 3.6 | 3.6 | 2.5 | 2.8 | 2.87 | 2.8 | 3 | 3.3 | 3.3 | 3.5 | 3.9 | 3.6 | 3.6 | 3.7 | 4.1 |

| W | 1.6 | 1.6 | 2 | 2.2 | 2.2 | 2.2 | 2.2 | 1.6 | 1.62 | 1.62 | 1.62 | 2 | 2.2 | 2.2 | 2.2 | 2.2 | 2.2 | 2.2 | 2.2 | 2.3 | |

| H | 1.2 | 1.2 | 1.5 | 1.8 | 1.8 | 1.8 | 1.8 | 1.2 | 1.2 | 1.2 | 1.2 | 1.5 | 1.8 | 1.8 | 1.8 | 1.8 | 1.8 | 1.8 | 1.9 | 1.9 | |

| Please note:As required customizable. | |||||||||||||||||||||

BOYU cold forming machine for nut making 19B-60B

| Item | 19B6S | 19B40LT | 19B60LT | 19B80LT | 22B30LT | 22B60LT | 24B30LT | 24B40LT | 24B60LT | 24B80LT | 27BT | 27B60LT | 27B90LT | 33B50LT | 33B100LT | 33B150LT | 41B60LT | 50B | |

| Forging station(mm) | 6s | 6s | 6s/7s/9s | 6s/7s | 6s | 6s | 6s | 6s | 6s/7s | 6s/7s | 6S | 6S | 6s/7s | 6S | 6S | 7S | 6S | 6S | |

| Max. cut-off diameter(mm) | 19 | 19 | 19 | 19 | 22 | 22 | 24 | 24 | 24 | 24 | 27 | 27 | 27 | 33 | 33 | 33 | 41 | 40 | |

| Cut-off length(mm) | 10 ~ 28 | 10 ~ 42 | 14.2 ~ 62 | 28 ~ 84 | 12 ~ 33 | 25 ~ 70 | 14 ~ 32 | 16 ~ 40 | 25 ~ 68 | 30 ~ 85 | 14.7 ~ 32 | 26 ~ 68 | 30 ~ 93 | 12 ~ 54 | 34 ~ 102 | 40 ~ 160 | 15 ~ 68 | 60 | |

| Kick-Out Length(mm) | 35 | 50 | 70 | 91 | 40 | 72 | 39 | 46 | 70 | 90 | 40 | 70 | 98 | 60 | 108 | 162 | 75 | 60 | |

| Center Distance(mm) | 80 | 80 | 80 | 80 | 90 | 90 | 100 | 100 | 100 | 100 | 110 | 110 | 110 | 140 | 140 | 140 | 165 | 200 | |

| Forging Power(Ton) | 200 | 200 | 260 | 260 | 270 | 270 | 280 | 280 | 300 | 300 | 300 | 300 | 330 | 330 | 350 | 400 | 600 | 860 | |

| Main motor(HP) | 40 | 40 | 60 | 60 | 60 | 75 | 60 | 60 | 100 | 100 | 100 | 100 | 125 | 180 | 220 | 272 | 272 | 272 | |

| Oil consumption (about 200L per barrel) No.8 or No.10 cold heading oil | 1600L | 1600L | 1600L | 1600L | 2000L | 2000L | 2600L | 2600L | 2600L | 2600L | 3200L | 3200L | 3200L | 4800L | 4800L | 4800L | 5600L | 8200L | |

| Machinery weight(Ton) | 16T | 18.5T | 19T/21T/30T | 19.5T/21T | 22T | 23T | 26T | 26.2T | 32T/34T | 34T/37T | 33T | 35T | 39T/43T | 49T | 70T | 80T | 87T | 118T | |

| Size(m) | L | 3.8 | 3.8 | 4.7 | 4.9 | 4.4 | 5 | 4.8 | 4.8 | 5.4 | 5.6 | 5 | 5.3 | 5.5 | 5.7 | 6.7 | 7.4 | 6.6 | 8.8 |

| W | 2.3 | 2.3 | 2.4 | 2.4 | 2.4 | 2.5 | 2.8 | 2.8 | 2.9 | 2.9 | 2.8 | 2.8 | 3 | 3.4 | 3.6 | 3.9 | 3.5 | 4.5 | |

| H | 1.9 | 1.9 | 2.1 | 2.1 | 2.1 | 2.1 | 2.2 | 2.2 | 2.2 | 2.3 | 2.4 | 2.4 | 2.5 | 2.5 | 2.5 | 2.6 | 2.7 | 3.2 | |

| Please note:As required customizable. | |||||||||||||||||||

Factory Tour

●Safety protection device - machine failure automatically stops ●Fault Detector - Automatic alarm for abnormal operation of the machine ●Temperature sensor - Monitoring the sliding bearing and crankshaft operating temperature at all times ●Counter - Statistics on the number of jobs ●Improve accuracy - Implement closed-loop control of position, speed and torque to overcome the problem of inch-in ●Adaptability - strong anti-overload capability, instantaneous load fluctuation

●Safety protection device - machine failure automatically stops ●Fault Detector - Automatic alarm for abnormal operation of the machine ●Temperature sensor - Monitoring the sliding bearing and crankshaft operating temperature at all times ●Counter - Statistics on the number of jobs ●Improve accuracy - Implement closed-loop control of position, speed and torque to overcome the problem of inch-in ●Adaptability - strong anti-overload capability, instantaneous load fluctuation