Specification

| Item | Unit | YK3608 | YKJ3608 |

| Max. working diameter | mm | Φ80 | Φ80 |

| Max. working module | mm | 2 | 1.5 |

| Workpiece spindle rpm | r/min | 400(600) | 400 |

| Hob spindle rpm | r/min | 2000 | 2000 |

| Hob shifting length | mm | 60 | 60 |

| Z-Slide travel | mm | 150 | 200 |

| Hob head swing angle | ° | ±40 | ±45 |

| Min. tooth number | - | 3 | 3 |

| Max. hob dia. X length | mm | Φ63×60 | Φ63×60 |

| Total power | KVA | 10 | 10 |

| Over all dimension (L/W/H) | mm | 2375×1880×2100 | 1650×1600×1900 |

| Machine weight | T | 3 | 3 |

Characteristic

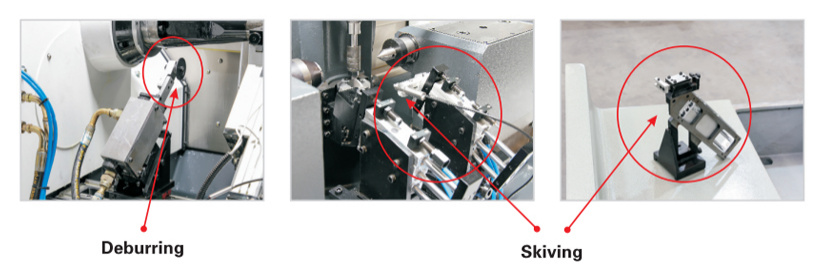

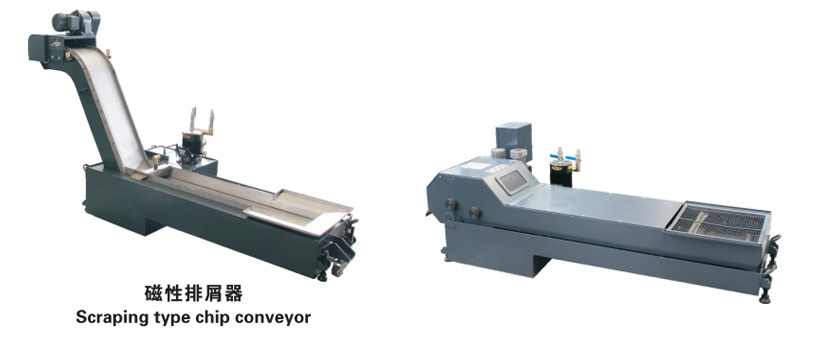

● FANUC Oi-MF/H control system ● 5 axes with b, c, x. Z-axis been simultaneously controlled. ● Direct coupling servo motor for B-axis. ● Servo driven for C-axis with high precision gear pair to achieve high torque. ● Servo control hob shifting(Y-axis)to reduce hob wear. ● Self-developed communication programming software make the machine operation more easy. ● Optional skiving accessory for 2nd hobbing of hardened gear. ● YK3608/1 with large helix angle designed specially for finishing tool gear production. ● Suitable for spur gear, helix gear, worm and spline.Gear hobbing machine accessories: